The HS420 is designed with your future in mind. A heavy-duty high-quality hydraulic proportional carriage, it is built with the ability to convert linear positioning at a later date. Perfect for start up operations working within tight budgets, it also adds value if sold used, allowing potential buyers to easily get the exact style of carriage desired – even converting to a simple air set if required.

Several options are available to meet your requirements for layout, production, log and cant turning, and maintenance.

Other Hydraulic Setwork Carriages

- Built from heavy-duty, thick-wall structural steel components, precision welded and finished — Rigid, accurate

- Horizontal or Tilt Frame – Meets customer needs, easily integrated into existing systems

- Two to five headblocks set at customer specified spacing – Meets customer needs for log lengths and mixes

- Larger/heavier than the 360 and 380 Series – Longer life, less maintenance, higher production

- Heavy-duty fabricated 3/4” bunks utilize long lasting 5/8” alloy steel wear plates – can be replaced to extend overall carriage life

- Knees are precision fabricated from 1” solid steel bases and two 1/2” side plates – longer lasting, more durable

- Knees attach to bunks with a wrap-around mount for stability – extremely accurate lumber, high durability, less maintenance

- Adjustable, replaceable synthetic wear strips on the top, bottom, and sides of knee mounts – maintains perfect fit, easy maintenance, long life

- Adjustable rack and pinion knee positioning – Precise, eliminates excessive maintenance of chain drives

- 1” Thick T1 alloy steel tong-dogs are center mounted within the knees – Increased accuracy comes from exceptional positioning and security.

- PawTaw Services Setworks – Minimizes training time, increases accuracy, yield, production

- High torque hydraulic motor and premium grade proportional valve for fast ramping, quick movement – High production, accuracies within .005”

- 10 HP hydraulic power pack with 5 gallon accumulator – mimimal maintenance, increased production

- OSHA approved air lock-out assembly — Increased employee safety

- Easy to access grease fittings, oversized oil cups — Easy maintenance

- OSHA approved air lock-out assembly – Increased employee safety

- Easy to access grease fittings, oversized oil cups – Easy maintenance

- Two, three, and four head block carriages available

- Any head block spacing available to meet customer’s specific requirements

- Custom built frames to meet elevation challenges

- Custom tilted frames

- Anti derailer

- Axles through the frame

- Custom axles centers to fit existing rail centers

- Custom wheel machining to match existing rail profile

- Extra wheel and axle assemblies

- Plastic wheels

- 14” wheels and 2 ¾” axles

- Brownsville turners

- Side mount turners

- On board Chain turners

- 3 Position face plates

- Cant push offs

- Double bit hammer dog

- Custom cable hook ups

- Dual cable equalizer systems

- Shot gun bracket

- Valve heaters

- Track and wheel cleaners

- Pressurized lube system for wheels and rail

- Automatic injection lube system for knees, wheels and rail

- Blow offs

- Nitride Process wear plates

- Chromed wear plates

- Carriage Frame is 1/2″ wall 6″ x 8″ tube on front & 1/2″ wall 4″ x 8″ tube on back, welded into a one piece rigid frame for extreme durability and maximum strength.

- Upgradeable to a linear positioning

- Axles are 2 1/2″ Solid square with 58″ wheel centers

- Wheels are 12″ Steel with Timken tapered roller bearings

- Ratchet cable tightener on front end and cable hook-up on the back end

- Heavy duty fabricated bunks with 3/4″ sides

- Long lasting Alloy steel wearplates 5/8″ thick

- Adjustable rack & pinion on each knee provides for maximum accuracy

- Knees are 1″ base & 1/2″ sides with center dog construction

- Grease fittings on dog hinge pins & oil cups on knee base

- Fully adjustable sandwich plate design uses replaceable wearstrips on top, sides and bottoms of wearplates to maintain a perfect fit

- 5″ infinite tapers with 4″bore taper cylinders

- Dogs are 1″ thick, heat treated T1 Alloy steel for excellent log holding performance

- High torque hydraulic motor for outstanding power

- High quality hydraulic proportional valve for superior accuracy & control

- Mico hydraulic brake to ensure accuracy

- 5 gallon accumulator provides for unsurpassed smoothness & recovery

- High pressure, 10 micron 280 filter

- Paw Taw John computer system with Servo sensor probe

- Top quality air cylinders

- 3″ Bore dog cylinders, 15″ stroke

- Sawyers console and handles mounted on telescoping stand for easy installation

- Extremely high quality electrical cable between the console and the carriage for better flexibility, durability and longevity.

- OSHA requires air lock-out assembly

- Features & Benefits

-

- Built from heavy-duty, thick-wall structural steel components, precision welded and finished — Rigid, accurate

- Horizontal or Tilt Frame – Meets customer needs, easily integrated into existing systems

- Two to five headblocks set at customer specified spacing – Meets customer needs for log lengths and mixes

- Larger/heavier than the 360 and 380 Series – Longer life, less maintenance, higher production

- Heavy-duty fabricated 3/4” bunks utilize long lasting 5/8” alloy steel wear plates – can be replaced to extend overall carriage life

- Knees are precision fabricated from 1” solid steel bases and two 1/2” side plates – longer lasting, more durable

- Knees attach to bunks with a wrap-around mount for stability – extremely accurate lumber, high durability, less maintenance

- Adjustable, replaceable synthetic wear strips on the top, bottom, and sides of knee mounts – maintains perfect fit, easy maintenance, long life

- Adjustable rack and pinion knee positioning – Precise, eliminates excessive maintenance of chain drives

- 1” Thick T1 alloy steel tong-dogs are center mounted within the knees – Increased accuracy comes from exceptional positioning and security.

- PawTaw Services Setworks – Minimizes training time, increases accuracy, yield, production

- High torque hydraulic motor and premium grade proportional valve for fast ramping, quick movement – High production, accuracies within .005”

- 10 HP hydraulic power pack with 5 gallon accumulator – mimimal maintenance, increased production

- OSHA approved air lock-out assembly — Increased employee safety

- Easy to access grease fittings, oversized oil cups — Easy maintenance

- OSHA approved air lock-out assembly – Increased employee safety

- Easy to access grease fittings, oversized oil cups – Easy maintenance

- Options

-

- Two, three, and four head block carriages available

- Any head block spacing available to meet customer’s specific requirements

- Custom built frames to meet elevation challenges

- Custom tilted frames

- Anti derailer

- Axles through the frame

- Custom axles centers to fit existing rail centers

- Custom wheel machining to match existing rail profile

- Extra wheel and axle assemblies

- Plastic wheels

- 14” wheels and 2 ¾” axles

- Brownsville turners

- Side mount turners

- On board Chain turners

- 3 Position face plates

- Cant push offs

- Double bit hammer dog

- Custom cable hook ups

- Dual cable equalizer systems

- Shot gun bracket

- Valve heaters

- Track and wheel cleaners

- Pressurized lube system for wheels and rail

- Automatic injection lube system for knees, wheels and rail

- Blow offs

- Nitride Process wear plates

- Chromed wear plates

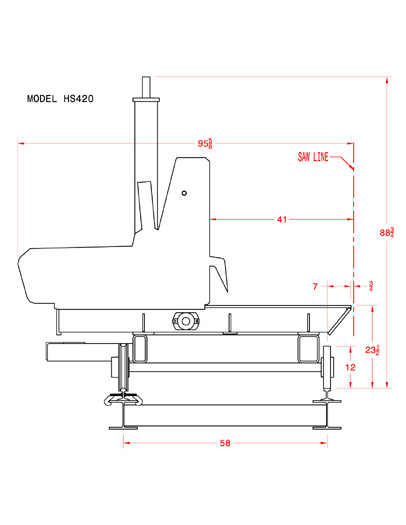

- Specifications & Dimensions

-

- Carriage Frame is 1/2″ wall 6″ x 8″ tube on front & 1/2″ wall 4″ x 8″ tube on back, welded into a one piece rigid frame for extreme durability and maximum strength.

- Upgradeable to a linear positioning

- Axles are 2 1/2″ Solid square with 58″ wheel centers

- Wheels are 12″ Steel with Timken tapered roller bearings

- Ratchet cable tightener on front end and cable hook-up on the back end

- Heavy duty fabricated bunks with 3/4″ sides

- Long lasting Alloy steel wearplates 5/8″ thick

- Adjustable rack & pinion on each knee provides for maximum accuracy

- Knees are 1″ base & 1/2″ sides with center dog construction

- Grease fittings on dog hinge pins & oil cups on knee base

- Fully adjustable sandwich plate design uses replaceable wearstrips on top, sides and bottoms of wearplates to maintain a perfect fit

- 5″ infinite tapers with 4″bore taper cylinders

- Dogs are 1″ thick, heat treated T1 Alloy steel for excellent log holding performance

- High torque hydraulic motor for outstanding power

- High quality hydraulic proportional valve for superior accuracy & control

- Mico hydraulic brake to ensure accuracy

- 5 gallon accumulator provides for unsurpassed smoothness & recovery

- High pressure, 10 micron 280 filter

- Paw Taw John computer system with Servo sensor probe

- Top quality air cylinders

- 3″ Bore dog cylinders, 15″ stroke

- Sawyers console and handles mounted on telescoping stand for easy installation

- Extremely high quality electrical cable between the console and the carriage for better flexibility, durability and longevity.

- OSHA requires air lock-out assembly