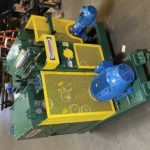

Cleereman Industries introduces the latest addition to a now complete line-up of primary breakdown machinery.

The new Cleereman edger line was produced following an extensive review of all major edgers currently available to locate fail-points and recurring maintenance issues with the goal of building the most efficient, durable and affordable optimized edger available today.

Poly belt drive system to eliminate chains and sprockets, huge 3 15/16” mandrels, full 1” thick main frames, revolutionary preliminary placement infeed table design, ductile saw collars, 8” chromed, knurled driven rolls, remote greasing and standalone oils system are just a few examples of how that is accomplished. The new line of Cleereman Optimized edgers utilizes Joe Scan heads and is available in many standard configurations including; optimized and non-optimized, 2 or 3 saw, 4” & 6” depth of cut, 42”-54” wide options and even combination gang models. In addition, every Cleereman edger comes with Cleereman Controls so you never deal with multiple vendors, providing a single point of contact for any unforeseen challenges for the life of your machine.

.jpg)

• Revolutionary Infeed Design for Accuracy & Low Maintenance

• Poly Drive System Eliminates Chains & Sprockets

• Industry Leading 3 15/16” Saw Mandrel

• FULL 1” Thick Main Frame

• Available Optimized or Non-Optimized (upgradable later)

• 2 or 3 Saw Board or 2 Saw Combo Gang Designs from 42”-54” Wide

• BEST OF ALL – Every Cleereman Edger Comes with Cleereman Controls and Optimization! No more dealing with multiple vendors!

- Features & Benefits

-

• Revolutionary Infeed Design for Accuracy & Low Maintenance

• Poly Drive System Eliminates Chains & Sprockets

• Industry Leading 3 15/16” Saw Mandrel

• FULL 1” Thick Main Frame

• Available Optimized or Non-Optimized (upgradable later)

• 2 or 3 Saw Board or 2 Saw Combo Gang Designs from 42”-54” Wide

• BEST OF ALL – Every Cleereman Edger Comes with Cleereman Controls and Optimization! No more dealing with multiple vendors! - Pictures

-