The Cleereman HS360 hydraulic proportional carriage carries on the Cleereman tradition of quality. Built using the best manufacturing practices, modern high-grade materials and quality components, the HS360 comes standard with high performance computer setworks. You can count on this package to be accurate, productive, dependable, and profitable.

Several options are available to meet your requirements for layout, production, log and cant turning, and maintenance.

Other Hydraulic Setwork Carriages

- Built from heavy-duty, thick-wall structural steel components, precision welded and finished — Rigid, accurate

- Horizontal or Tilt Frame — Meets customer needs, easily integrated into existing systems

- Two to five headblocks set at customer specified spacing — Meets customer needs for log lengths and mixes

- Fabricated bunks utilize steel wear plates — Long-lasting, can be replaced to extend overall carriage life

- Knees are precision fabricated from 1” steel bases and 3/4” solid steel uprights – longer lasting, more durable

- Knees attach to bunks with a wrap-around mount for stability – extremely accurate lumber, high durability, less maintenance

- Adjustable, replaceable synthetic wear strips on the top, bottom, and sides of knee mounts – maintains perfect fit, easy maintenance, long life

- Adjustable rack and pinion knee positioning — Precise, eliminates excessive maintenance of chain drives

- T1 alloy steel tong-dogs — Holds log firmly in place for sure positioning

- PawTaw Services Setworks – Minimizes training time, increases accuracy, yield, production

- High torque hydraulic motor and premium grade proportional valve for fast ramping, quick movement – High production, accuracies within .005”

- 10 HP hydraulic power pack with 5 gallon accumulator – mimimal maintenance, increased production

- OSHA approved air lock-out assembly — Increased employee safety

- Easy to access grease fittings, oversized oil cups — Easy maintenance

- Two, three, four and five head block carriages available

- Any head block spacing available to meet customer’s specific requirements

- Custom built frames to meet elevation challenges

- Custom tilted frames

- Built in rub rail

- Anti de-railer

- Axles through the frame

- Custom axle centers to fit existing rail centers

- Custom wheel machining to match existing rail profile

- Extra wheel and axle assemblies

- Plastic wheels

- 14” wheels and 2 ¾” axles

- Brownsville turners

- Bottom Dog cant turners

- 3 Position face plates

- Cant push offs

- Board push offs

- Cant flippers

- Single bit hammer dog

- Custom cable hookups

- Dual cable equalizer systems

- Shot gun bracket

- Valve heaters

- Track and wheel cleaners

- Pressurized lube system for wheels and rail

- Automatic injection lube system for knees, wheels and rail

- Blow offs

- Nitride Process wear plates

- Chrome wear plates

- Carriage Frame: 1/2″ wall 6″ x 6″ tube on front & 1/2″ wall 4″ x 6″ tube on back, welded into a one piece rigid frame for extreme durability and maximum strength.

- Axles: 2 1/2″ Solid square with 50″ wheel centers

- Wheels: 12″ Steel with Timken tapered roller bearings

- Ratchet cable tightener on front end and cable hook-up on back end

- Heavy duty fabricated bunks with long lasting Alloy steel wear plates

- Adjustable rack and pinion on each knee provides for maximum accuracy

- Knees: 3/4″ x 8″ base & 3/4″ upright with grease fittings installed for dog hinge pins

- Replaceable synthetic wearstips under the knees and oversized oil cups

- 5″ Infinite tapers and fully adjustable face plates to ensure perfect squareness

- Dogs: 3/4″ Thick, heat treated T1 Alloy steel for excellent log holding performance

- High torque hydraulic motor for outstanding power

- High quality hydraulic proportional valve for superior accuracy and control

- Mico hydraulic brake to ensure accuracy

- 5 gallon accumulator provided for unsurpassed smoothness and recovery

- High pressure, 10 micron 280 filter

- Paw Taw John computer system with Servo sensor probe

- Extremely high quality electrical cable between the console and the carriage for better flexibility, durability and longevity

- Mac air valves

- Wilkerson coalescing air filter and lubricator

- Sawyers console and handles mounted on telescoping stand for easy installation

- OSHA required air lock out assembly

- Features & Benefits

-

- Built from heavy-duty, thick-wall structural steel components, precision welded and finished — Rigid, accurate

- Horizontal or Tilt Frame — Meets customer needs, easily integrated into existing systems

- Two to five headblocks set at customer specified spacing — Meets customer needs for log lengths and mixes

- Fabricated bunks utilize steel wear plates — Long-lasting, can be replaced to extend overall carriage life

- Knees are precision fabricated from 1” steel bases and 3/4” solid steel uprights – longer lasting, more durable

- Knees attach to bunks with a wrap-around mount for stability – extremely accurate lumber, high durability, less maintenance

- Adjustable, replaceable synthetic wear strips on the top, bottom, and sides of knee mounts – maintains perfect fit, easy maintenance, long life

- Adjustable rack and pinion knee positioning — Precise, eliminates excessive maintenance of chain drives

- T1 alloy steel tong-dogs — Holds log firmly in place for sure positioning

- PawTaw Services Setworks – Minimizes training time, increases accuracy, yield, production

- High torque hydraulic motor and premium grade proportional valve for fast ramping, quick movement – High production, accuracies within .005”

- 10 HP hydraulic power pack with 5 gallon accumulator – mimimal maintenance, increased production

- OSHA approved air lock-out assembly — Increased employee safety

- Easy to access grease fittings, oversized oil cups — Easy maintenance

- Options

-

- Two, three, four and five head block carriages available

- Any head block spacing available to meet customer’s specific requirements

- Custom built frames to meet elevation challenges

- Custom tilted frames

- Built in rub rail

- Anti de-railer

- Axles through the frame

- Custom axle centers to fit existing rail centers

- Custom wheel machining to match existing rail profile

- Extra wheel and axle assemblies

- Plastic wheels

- 14” wheels and 2 ¾” axles

- Brownsville turners

- Bottom Dog cant turners

- 3 Position face plates

- Cant push offs

- Board push offs

- Cant flippers

- Single bit hammer dog

- Custom cable hookups

- Dual cable equalizer systems

- Shot gun bracket

- Valve heaters

- Track and wheel cleaners

- Pressurized lube system for wheels and rail

- Automatic injection lube system for knees, wheels and rail

- Blow offs

- Nitride Process wear plates

- Chrome wear plates

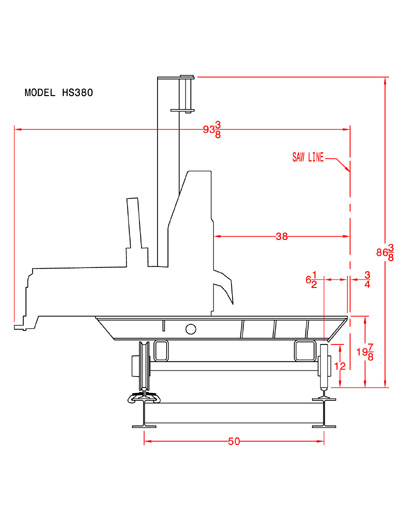

- Specifications & Dimensions

-

- Carriage Frame: 1/2″ wall 6″ x 6″ tube on front & 1/2″ wall 4″ x 6″ tube on back, welded into a one piece rigid frame for extreme durability and maximum strength.

- Axles: 2 1/2″ Solid square with 50″ wheel centers

- Wheels: 12″ Steel with Timken tapered roller bearings

- Ratchet cable tightener on front end and cable hook-up on back end

- Heavy duty fabricated bunks with long lasting Alloy steel wear plates

- Adjustable rack and pinion on each knee provides for maximum accuracy

- Knees: 3/4″ x 8″ base & 3/4″ upright with grease fittings installed for dog hinge pins

- Replaceable synthetic wearstips under the knees and oversized oil cups

- 5″ Infinite tapers and fully adjustable face plates to ensure perfect squareness

- Dogs: 3/4″ Thick, heat treated T1 Alloy steel for excellent log holding performance

- High torque hydraulic motor for outstanding power

- High quality hydraulic proportional valve for superior accuracy and control

- Mico hydraulic brake to ensure accuracy

- 5 gallon accumulator provided for unsurpassed smoothness and recovery

- High pressure, 10 micron 280 filter

- Paw Taw John computer system with Servo sensor probe

- Extremely high quality electrical cable between the console and the carriage for better flexibility, durability and longevity

- Mac air valves

- Wilkerson coalescing air filter and lubricator

- Sawyers console and handles mounted on telescoping stand for easy installation

- OSHA required air lock out assembly